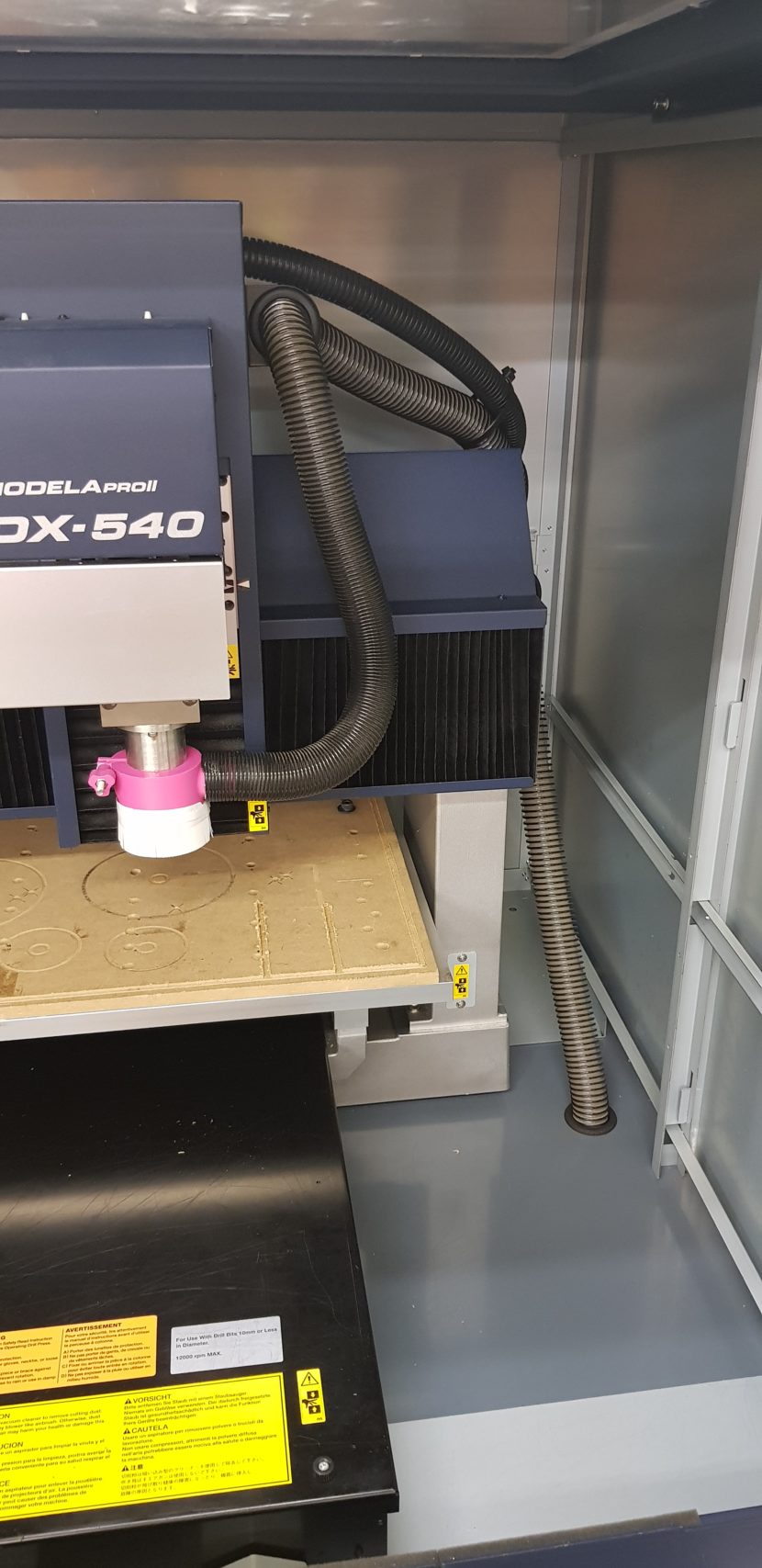

Mercedes CLK (W209) Self Levelling Centre Caps

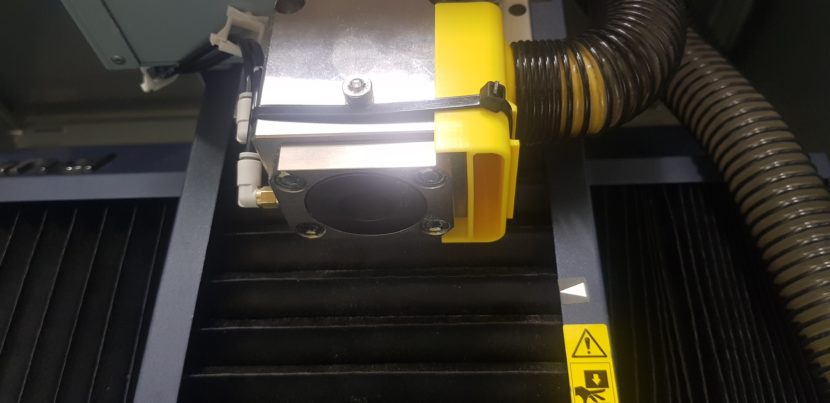

An alloy wheel centre cap for the Mercedes CLK alloy wheels. The design uses lead weights, with hybrid ceramic bearings to allow it move freely and level itself with as little friction as possible. The 4 part design allows the cap to be disassembled and repaired if necessary.