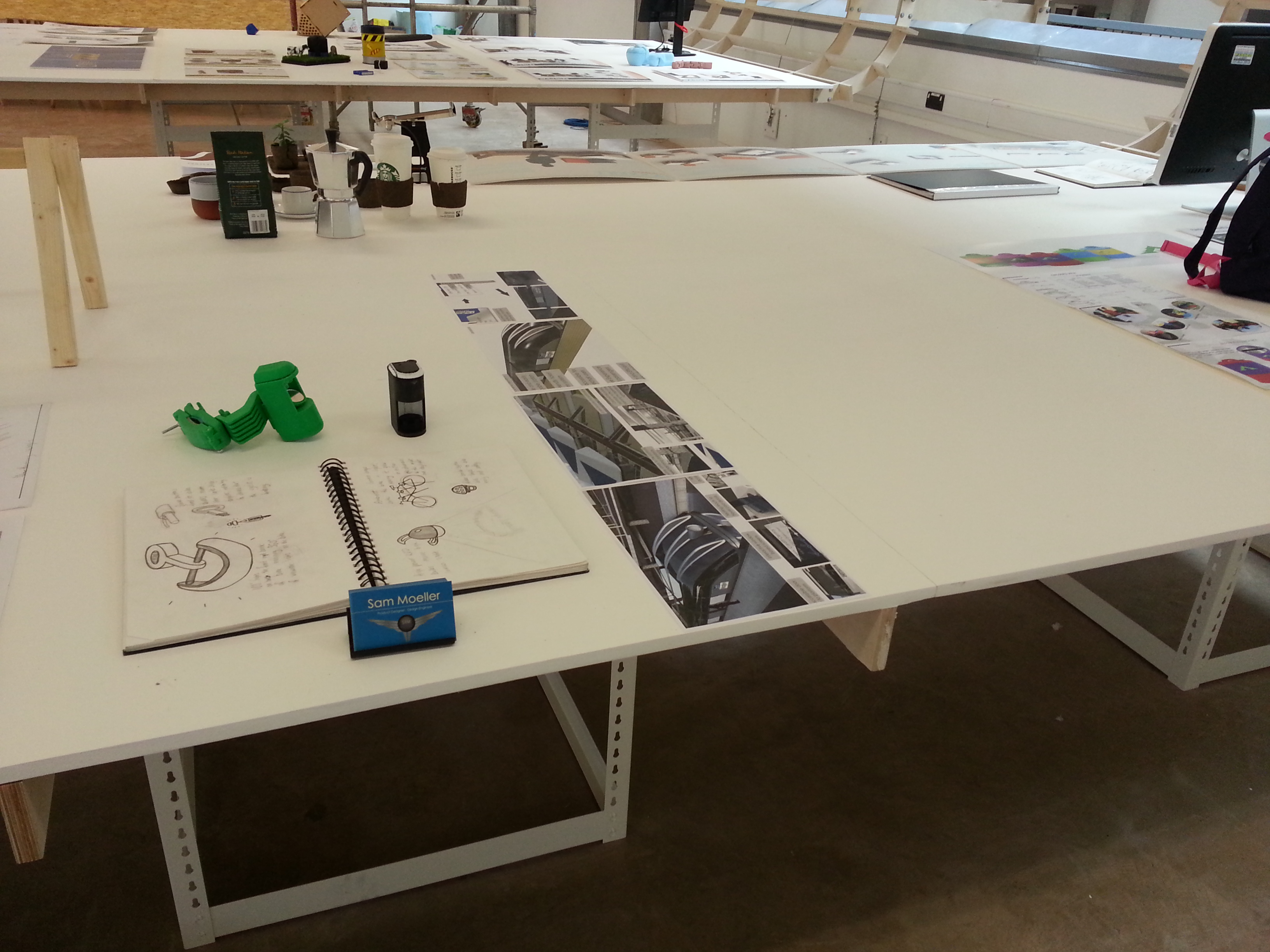

Finishing touches

So my viva presentation is tommorow and I have been working to get everything finalised for my presentation, including my board designs and most importantly, this damn prototype… So I have printed all the parts now and painted them too! I’m just sincerely hoping all goes well for my viva presentation! Oh and this happened to my beloved desk at home, due to a miscalculation with super glue, the glass bed of my 3D printer and the glass panel on my desk: Fun!